Rock gold processing plant is the most efficient method to separate and recovery the old in rock gold mine. The recovery rate can be more than 95% after using gravity concentration and gold CIL (carbon in leaching) ways. The most single coarse gold ore can be separated by the gravity concentration, the fine gold and some gold tailings can be separated by the CIL gold leaching cyanidation ways. It is the first choice of modern gold concentration and gold processing plant.

Gold processing equipment:

Rock gold processing machine mainly applies for the process of 1-7g/t grade gold ore and gold ore with large bearing ore volume: silver, platinum, copper, etc. As CIL has a better performance in extracting these minerals at the same time. And Hengchang Mining Machinery can help you with the component testing of your ores.

Introduction of rock gold processing plant:

1. Crushing and grinding system

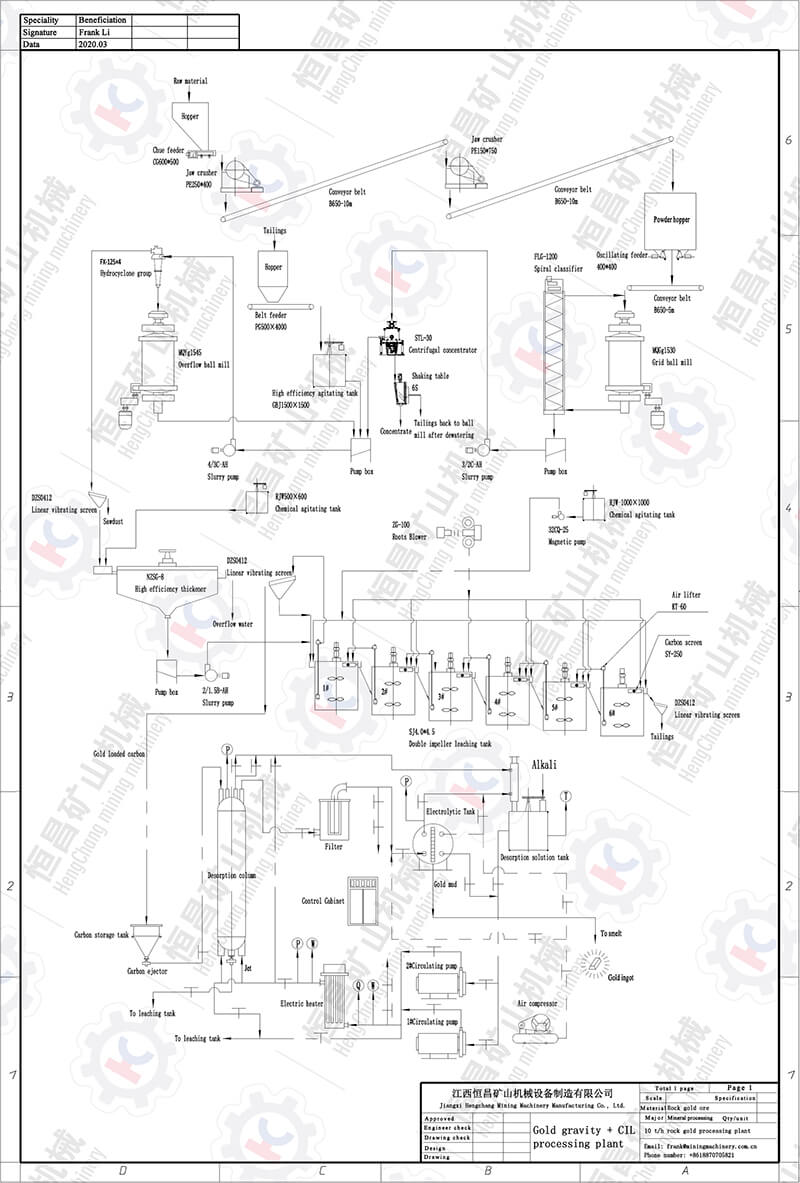

Raw gold ores→vibrating feeder→primary crusher→secondary crusher→vibrating screen→ball mill→spiral classifier→gravity separation→ball mill→hydrocyclone group→thickener

2. After the crushing and grinding stage, the thickened materials will enter into 9 step-arranged high-efficiency cyanidation leaching tanks. Gold pulp cyanidation is carried on the first two leaching tanks, countercurrent adsorption operation is carried on the last six or seven leaching tanks (cyanidation and adding activated carbon simultaneously).

3. In the adding activated carbon step, add the coconut shell activated carbon (small hole, high activity, wear-resisting and renewable) specially selected by Hengchang Mining Machinery mineral processing design institute into the pulp, which can dissolve and adsorb the gold and silver ions then form the gold loaded carbon according to the characteristics of gold and silver adsorption.

4. Vibrating screen and dewatering screen are the key equipment for the reverse movement of pulp and carbon. Filter press and high frequency dewatering screen can effectively reduce the carbon wear on the surface of vibrating screen and in the process of continuous slurry pumping, and reduce the cost, facilitate the maintenance and operation.

Air lifter used in the agitation process can make the slurry carry on small minor-cycle. Air lifters reduces the power consumption by 70%, and make the solid materials suspend uniformly, the wear of activated carbon is small, and the recovery of gold is high, which is an important equipment in the modern gold leaching plant.

5. Desorption electrolysis system implements high-temperature desorption electrolysis on gold in the gold-loaded carbon through the mixed liquor of sodium cyanide and sodium hydroxide. After wood chips and other sundries are removed by washing machine, and the gold desorption is carried out by high-temperature and high-pressure desorption method (150 degrees and 0.5Mpa), which can resolve 99% of gold within 2-6 hours. After getting the gold mud from desorption electrolysis system, the gold mud will go to gold melting furnace and turns to the gold bar.